In the field of HDPE geomembrane welding, accuracy and reliability are paramount. The American Society for Testing and Materials (ASTM) has established standards for the quality of HDPE geomembrane welds.

Recent additions to the ASTM standards – D8580-24 & D8468-23 – introduce new guidance and guidelines to enhance HDPE membrane application standards.

Leister HDPE Welders ensures that its equipment not only meets but exceeds these new standards.

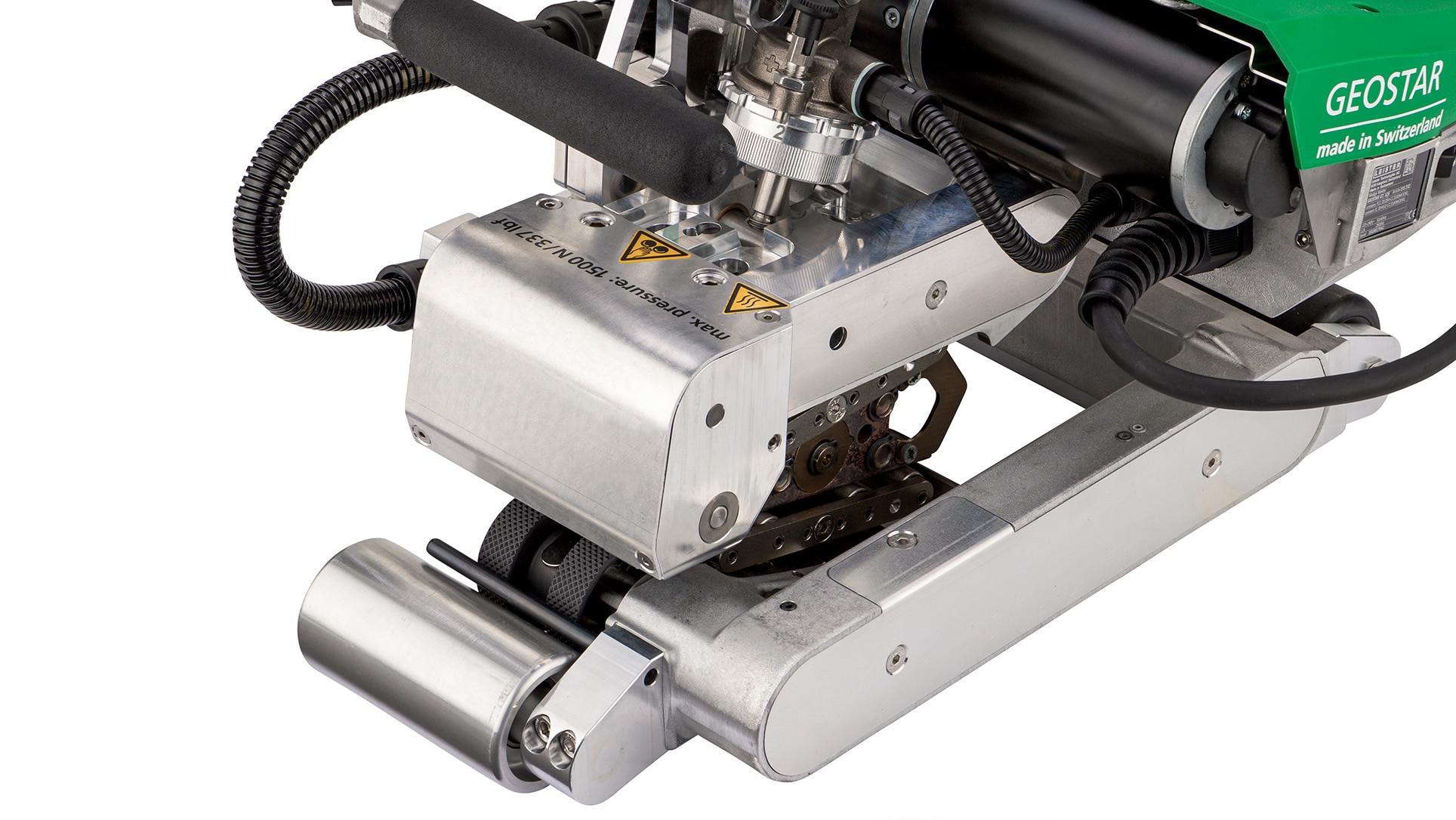

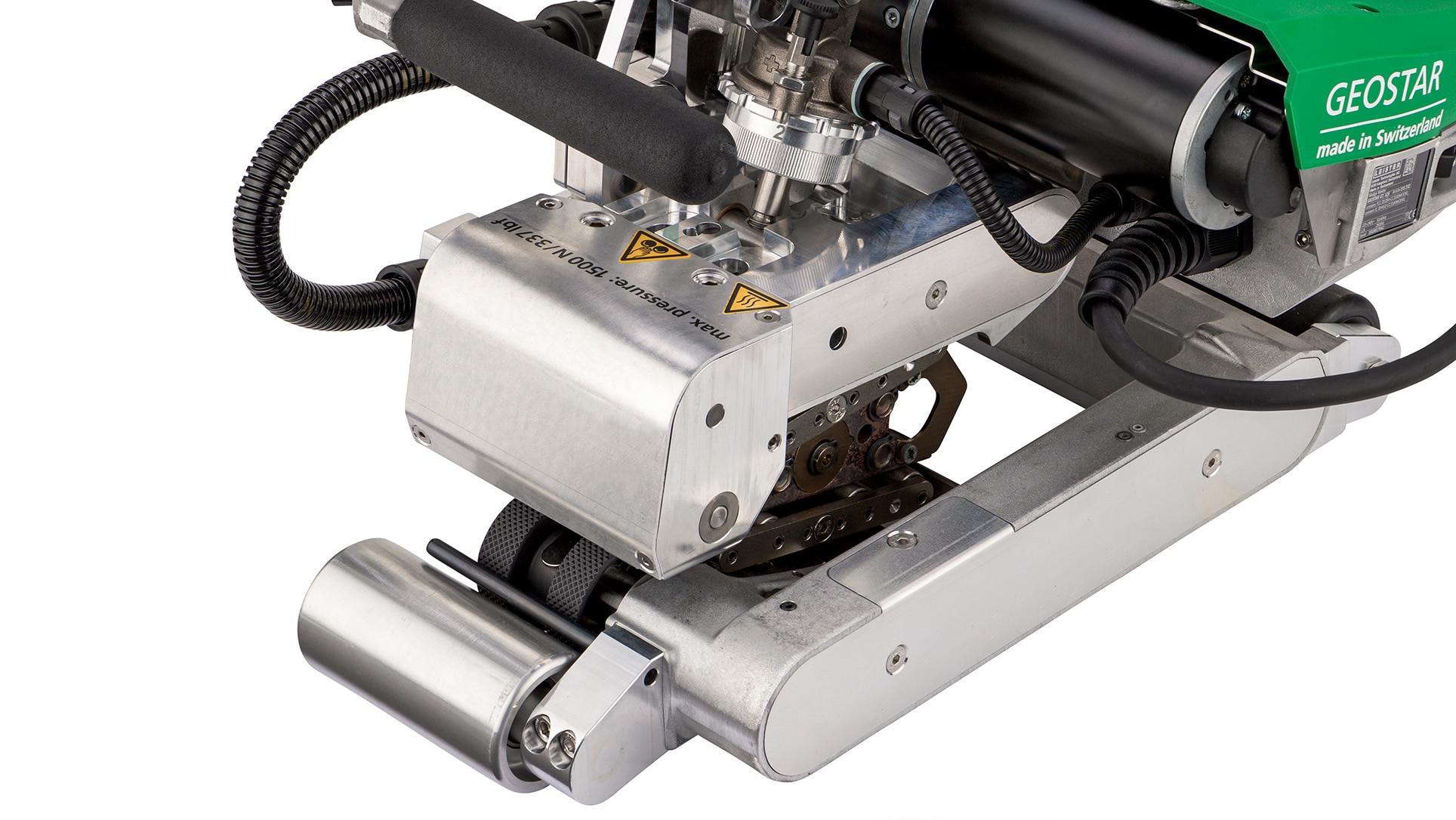

ASTM D8580-24: Elevating Wedge Welding Practices

The newly published ASTM D8580-24 provides a comprehensive framework for Wedge Welding of polymer waterproofing membranes. This standard is designed to improve weld quality and consistency by establishing clear parameters for the welding process and equipment. Key highlights of this standard include:

- In-process welding parameters display: Welding equipment must display all three critical welding parameters – Temperature, Speed & Pressure – ensuring that the operator can closely monitor and adjust settings in real time.

- Closed-loop electronic control systems: Heat and speed should be controlled by closed-loop systems, which enhance accuracy and consistency throughout the welding process.

- Pressure Accuracy: Accurate Pressure readings are critical to achieving high-quality welds and these standards require welders to display pressure with accuracy, allowing operators to observe the welding process.

- Equipment Design: Welders should be designed without sharp edges that could damage the waterproof membrane, ensuring a smooth and efficient welding process.

- Welding Data Collection: The inclusion of a data collection system is recommended to aid in quality control and provide valuable insights into the welding process.

Leister welding equipment is designed to perfectly match these requirements. Our machines offer integrated displays for welding parameters, advanced closed-loop control systems, and accurate pressure readings. Additionally, our equipment design prioritizes safety and efficiency, eliminates sharp edges, and includes robust data collection features.

ASTM D8468-23: Enhanced Data Recording for Quality Assurance

ASTM D8468-23 introduces rigorous protocols for data recording during fusion welding of waterproof membranes. The standard focuses on:

- Minimum Data Requirements: Establishing the necessary data that must be recorded during the welding process to ensure thorough quality control and detect any anomalies.

- Post-weld Analysis: Using recorded data for comprehensive post-weld analysis, allowing verification that welds meet required quality levels.

Leister’s commitment to quality is reflected in our advanced data recording capabilities. Our equipment is designed to integrate seamlessly with data acquisition systems, providing detailed records of every welding operation. This feature is critical for both quality control and post-weld analysis, ensuring that all projects adhere to the highest performance standards.

Leister: is a pioneer brand in upgrading & improving equipment for HDPE geomembrane welding equipment

By complying with the latest ASTM standards, Leister reinforces its position as a leader in HDPE geomembrane welding technology. Our equipment is not only compliant with the new guidelines, but is also designed to help customers stay ahead of industry requirements. Investing in a Leister welder means investing in reliability, precision, and future-ready technology.

For customers, this means an enhanced ability to handle projects that require these new standards, ensuring both compliance and superior performance. As the geomembrane industry evolves, Leister remains dedicated to supporting its customers with innovative solutions that meet and exceed the latest ASTM standards.

In summary, the new ASTM standards D8580-24 and D8468-23 mark a significant advancement in geomembrane welding, and Leister is proud to lead the way with equipment that meets these enhanced criteria. With our technology, customers can achieve the highest welding quality and efficiency, ensuring the success of their projects and contributing to a sustainable future.

LinkTải về tiêu chuẩn ASTM:

D8580-24

D8580 Standard Practice for Wedge Welding of Polymeric Geomembranes (astm.org)

D8468-23

D8468 Standard Practice for Data Recording Procedure for Welding Devices Used to Produce Thermal Fusion Welds in Geomembrane Systems (astm.org)