-

About Us

-

About Dong Loi

Dong Loi Equipment & Services Corporation, established in 2002 in Ho Chi Minh City with branches in Dong Nai and Ha Noi, is a leading provider of technical services, industrial, construction and mining equipment.

-

Tuyển dụng

-

About Dong Loi

- Product

- Máy cũ & Cho thuê

-

Services

-

Drifter of Rock drill machine

-

Service for Scrubber, Sweeper Machine

-

Buttom bit Grinding services

-

Maintenance

-

Spare parts for maintenance rock drill

-

Spare parts for repare Rock Drill Machine

-

Maintenance parts for Bobcat

-

Các loại lốp xe nâng

-

Bobcat spare part

-

Spare parts for repare Leister welding machine

-

Drifter of Rock drill machine

-

Service for Scrubber, Sweeper Machine

-

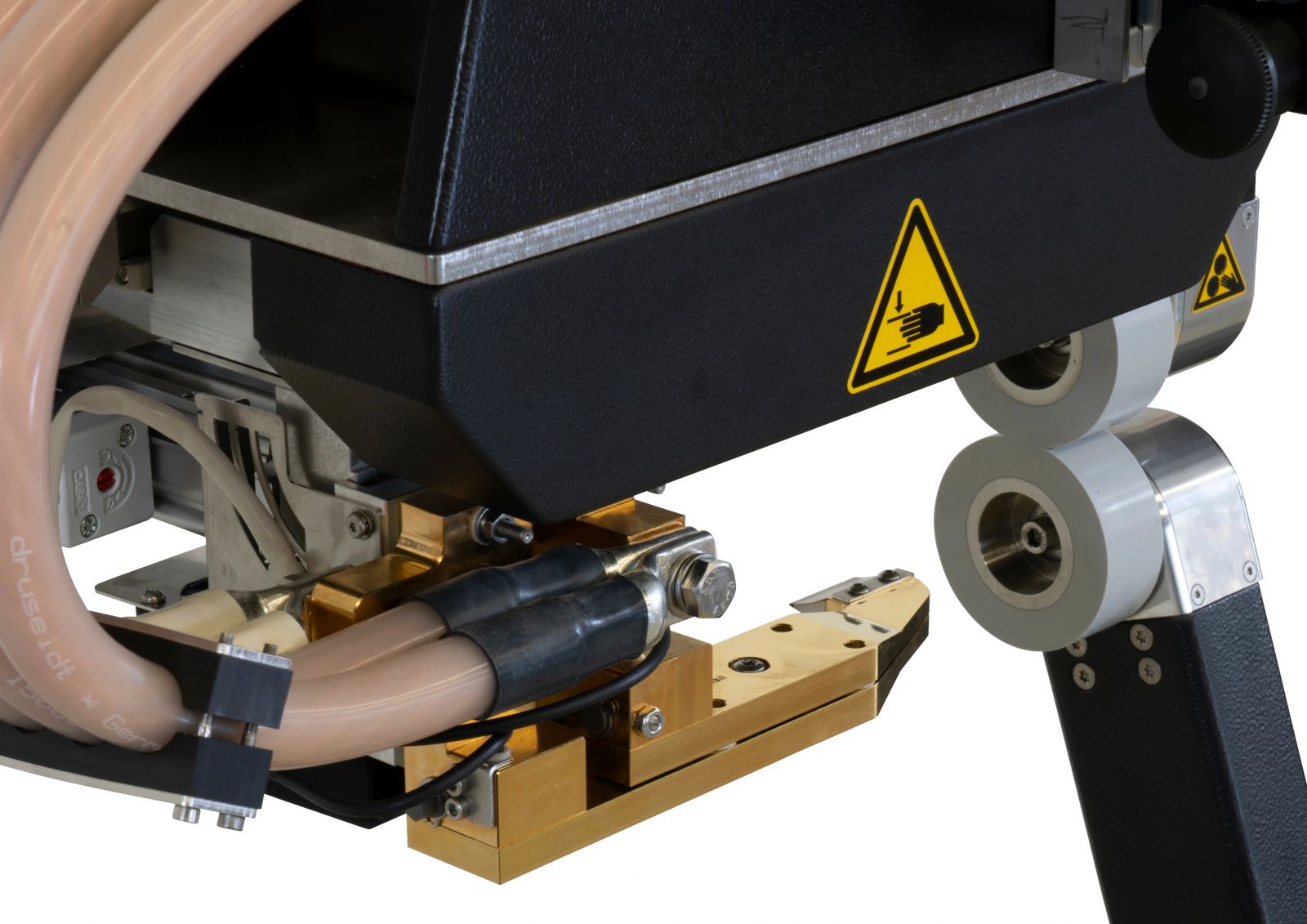

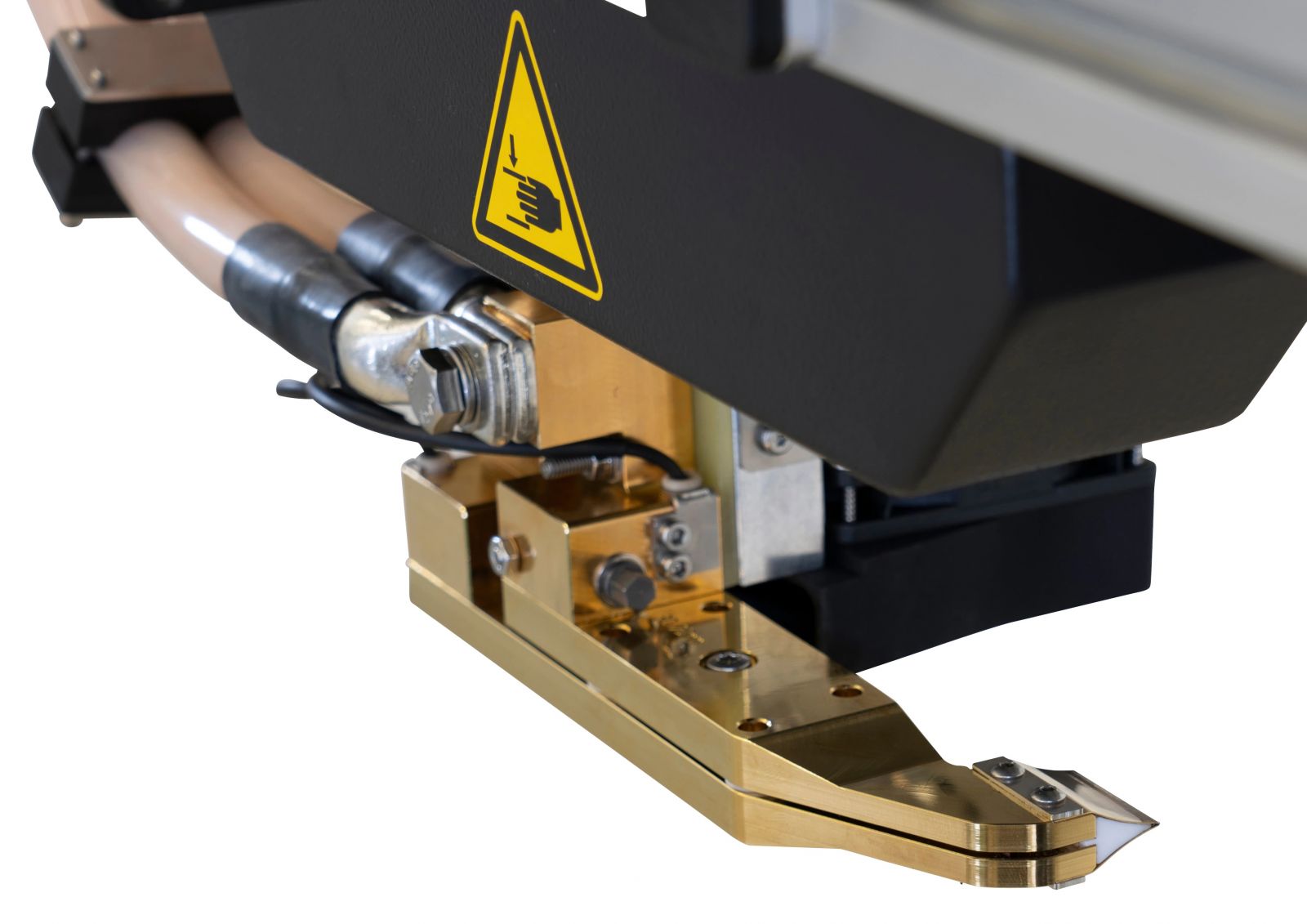

Buttom bit Grinding services

By design, bits and cutters are fitted with carbide buttons that have carefully selected profiles that contribute to optimum penetration levels for various drilling conditions. In order to crush rock effectively it is imperative to maintain a precise button protrusion and button profile for each carbide tip. To that end, CME has invested decades of research and development into engineering its patented grinding systems. When combined with a regular, comprehensive maintenance routine, these systems can effectively improve efficiencies and reduce operating costs. We also provide a range of accessories engineered to maximize resources and help your new or existing systems cope with challenging operating conditions.

-

Maintenance

-

Spare parts for maintenance rock drill

-

Spare parts for repare Rock Drill Machine

-

Maintenance parts for Bobcat

-

Các loại lốp xe nâng

Cung cấp các loại lốp hơi, lốp đặc cho xe nâng hàng, xe xúc lật các loại

-

Bobcat spare part

We provide all kinds of spare parts for Bobcat cars, 100% genuine commitment, high quality parts, good spare parts life, increase the life of the machine

-

Spare parts for repare Leister welding machine

- JCB construction machinery

-

Drifter of Rock drill machine

-

News

-

Activities

-

Tin chuyên ngành

Our Partner are: Leister - Swichtzeland, SkyJack - Canada, Bobcat - USA, Furukawa - Japan, ...

-

New Products

-

Technical Information

-

Activities

- Recruitment

- Contact Us